Main Types of Double Girder Gantry Cranes

Key Features of NYBON Double Girder Gantry Cranes

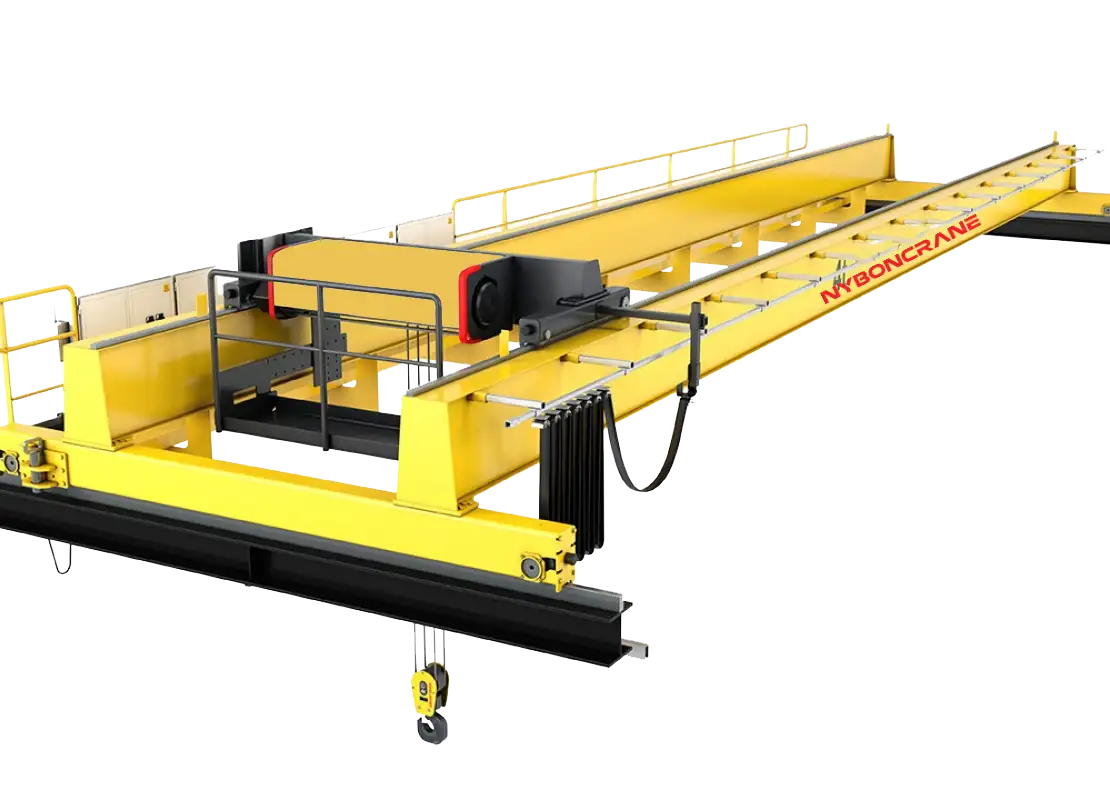

Robust double-girder steel structure for maximum strength and low deflection.

High-capacity performance up to 1,000+ tons with engineered safety margins.

Modular design for easier transport, on-site assembly, and maintenance.

Frequency inverter (VFD) options for smooth start/stop and better positioning.

Redundant safety devices: overload protection, limit switches, anti-collision systems.

Optional smart monitoring: load sensors, remote diagnostics, and data logging.

Surface protection for outdoor or corrosive environments (paint, galvanizing).

Compatible with specialized lifting attachments (magnets, grabs, C-hooks).

Applications of Double Girder Gantry Cranes

Steel mills and rolling plants — coil handling, slab transfer, and plate handling.

Shipyards — hull assembly, engine lifting, and heavy block transport.

Ports & terminals — container handling, heavy cargo transfer, and storage yards.

Heavy equipment manufacturing — assembly of large machines and press parts.

Power plants and hydropower stations — turbine and generator installation.

Mining and bulk material handling — ore transfer and stockpile management.

Prefab construction yards — moving large precast concrete elements.

Any large-scale industrial project requiring safe, reliable heavy lifting.

Why Choose NYBON Machinery?

Experience in heavy crane design and global projects.

Engineering team for structural customization.

Strict quality control and testing before shipment.

Fast technical support and worldwide spare parts.

Focus on safe, long-lasting, and cost-effective crane systems.

Send Us A Message