Single vs. Double Girder Gantry Crane: Which One Do You Need?

We have the best instructors

Choosing the right crane shouldn’t feel like rocket science. Whether you’re lifting heavy steel or moving warehouse pallets, the right girder setup changes everything.

What is the Main Difference?

The “girder” is the horizontal beam that supports the load. A single girder crane has one beam, while a double girder crane has two. This simple structural change affects how much weight you can lift, how high you can go, and how much you will pay.

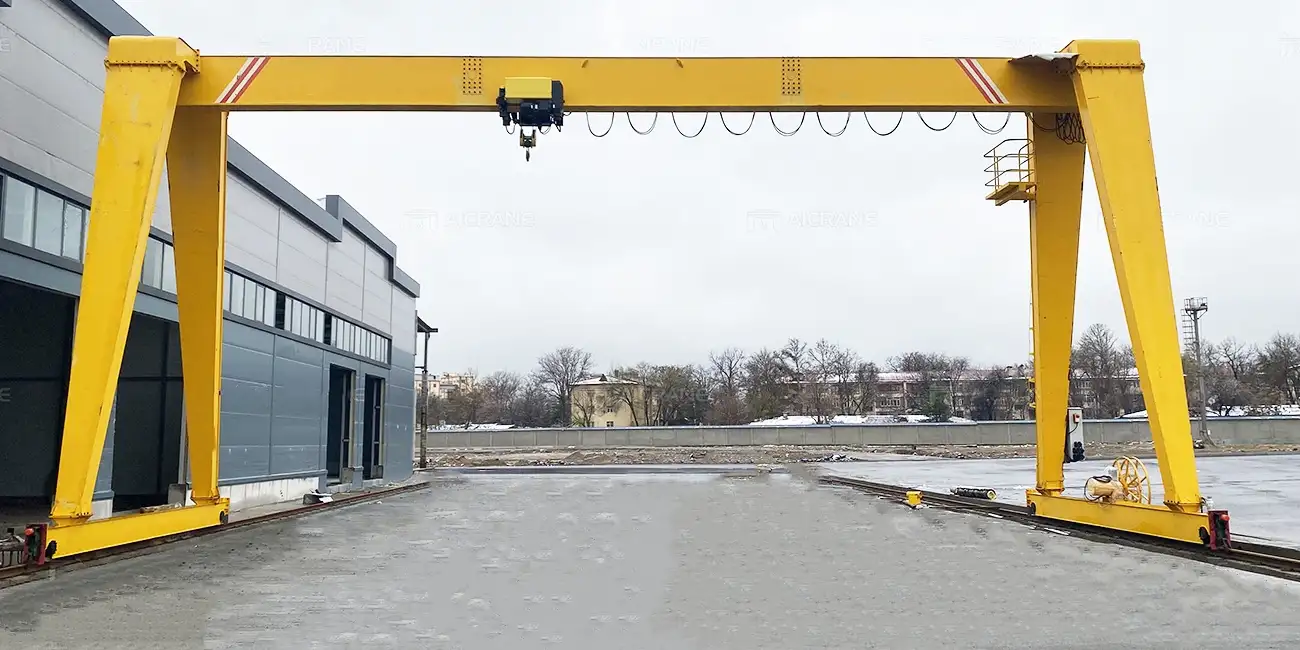

The single girder gantry crane is the go-to solution for most light to medium industrial tasks. It is efficient, easy to install, and very cost-effective.

When to Choose a Single Girder?

This is the best choice for capacities up to 20 tons and spans under 30 meters. If you run a workshop, a marble yard, or a small warehouse, this crane is likely your best friend.

Advantages

Budget-Friendly: Uses less steel and a simpler hoist, keeping your initial investment low.

Quick Setup: It is lighter and easier to transport and install on your site.

Low Maintenance: Fewer parts mean less time spent on repairs.

Space Efficient: Great for facilities with limited floor space.

When the job gets massive, the double girder gantry crane steps in. By using two beams, the crane gains incredible stability and can handle much higher capacities and heights.

When to Go Double?

If you are lifting over 20 tons or working in a heavy-duty environment like a shipyard or a steel plant, the double girder is necessary. It is built for constant, high-speed operation.

Advantages

Extreme Capacity: Can easily handle 50 tons, 100 tons, or even 500+ tons.

Better Lifting Height: The hoist sits between the beams rather than under them, allowing the hook to travel higher.

Greater Stability: Ideal for wide spans where a single beam might flex too much.

High Performance: Designed for heavy-duty cycles (A5 to A8), meaning it can work 24/7.

Technical Comparison at a Glance

| Feature | Single Girder Gantry Crane | Double Girder Gantry Crane |

|---|---|---|

| Lifting Capacity | 1 to 20 Tons | 20 to 500+ Tons |

| Span Length | Up to 30 meters | Custom Wide Spans |

| Lifting Height | Standard | High / Extra High |

| Duty Class | A3 – A5 | A5 – A8 |

| Cost | Budget-friendly | Premium Investment |

| Installation | Quick and Easy | More Complex |

3 Questions to Ask Before You Buy

What is your maximum weight? If it is under 15 tons, a single girder is usually enough.

How often will it run? If the crane is moving non-stop all day, a double girder offers better durability.

Does height matter? If you need every inch of lifting height for tall loads, the double girder design is superior.

Conclusion: Making Your Choice with Nybon Crane

At the end of the day, the best crane is the one that keeps your production moving safely and efficiently. Whether you need a simple single girder setup or a massive double girder system, Nybon Crane is here to help with custom engineering and reliable manufacturing.

Need a custom gantry crane solution for your project? Contact Nybon Crane Experts today for a free quote!

Frequently Asked Questions

1. Is a double girder crane safer than a single girder?

Both are safe when manufactured correctly. The double girder isn’t “safer”; it is simply stronger for heavier, more stressful industrial loads.

2. Which crane takes up less space?

Single girder cranes usually have a lower profile and weigh less, making them ideal for smaller workshops where floor space or overhead clearance is limited.

3. Can a single girder crane be used outdoors?

Yes. We frequently build single girder gantry cranes for outdoor use in marble yards and ports. We add protective covers for the motors and hoists to handle the weather.

4. Why is the double girder crane more expensive?

It requires more steel, a more powerful trolley system, and more complex engineering to handle high-production environments.

5. Can Nybon Crane customize the span and height?

Yes. Every factory is different. We can customize the span, height, and lifting speed of both single and double girder cranes to fit your specific rails and workflow.