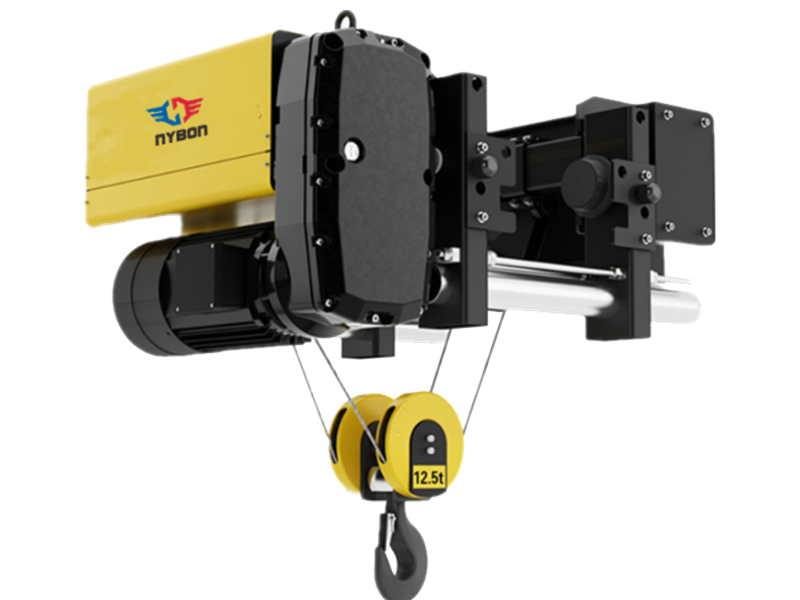

At NYBON Machinery, we understand that crane wheels are more than just components—they are critical to the performance and safety of lifting equipment. As a trusted manufacturer of industrial bridge cranes, gantry cranes, jib cranes, electric hoists, and crane accessories, we take pride in our meticulous crane wheel manufacturing process.

In this guide, we’ll walk you through each stage of our manufacturing process, highlighting how we ensure durability, precision, and reliability in every crane wheel we produce.

Understanding the Importance of Crane Wheels

Crane wheels are essential for the smooth operation of various types of cranes. They bear the load, facilitate movement along tracks, and endure significant stress during operations. A well-manufactured crane wheel ensures:

-

Longevity: Resisting wear and tear over extended periods.

-

Safety: Minimizing the risk of operational failures.

-

Efficiency: Ensuring smooth and precise movements.

The Crane Wheel Manufacturing Process at NYBON Machinery

1. Material Selection

Our process begins with selecting high-quality materials. We primarily use forged or cast steel, such as ZG55, ZG65, or 50SiMn, known for their strength and durability. The choice of material depends on the specific requirements of the crane application.nybongrua.com

2. Forging or Casting

Depending on the design specifications, the selected steel undergoes forging or casting. Forging enhances the internal structure of the metal, resulting in superior strength, while casting allows for complex shapes and sizes.

3. Rough Machining

Post forging or casting, the crane wheel undergoes rough machining to achieve the basic shape and dimensions. This step prepares the wheel for subsequent heat treatment and precision machining.

4. Heat Treatment

Heat treatment is crucial for enhancing the mechanical properties of the crane wheel. The process involves:

-

Hardening: Increasing surface hardness to resist wear.

-

Tempering: Reducing brittleness while maintaining strength.

This ensures the wheel can withstand the demanding conditions of crane operations.

5. Precision Machining

After heat treatment, the wheel undergoes precision machining to achieve exact dimensions and surface finishes. This step is vital for ensuring proper fit and function within the crane assembly.

6. Quality Inspection

Each crane wheel is subjected to rigorous quality inspections, including:

-

Dimensional Checks: Verifying all measurements meet specifications.

-

Hardness Testing: Ensuring the heat treatment achieved desired hardness levels.

-

Surface Inspection: Detecting any surface defects or irregularities.

These inspections guarantee that only wheels meeting our high standards proceed to the final stage.

7. Final Assembly and Packaging

Approved crane wheels are then assembled with any additional components, if required, and packaged securely for delivery. We ensure that each product reaches our clients in perfect condition, ready for installation.

Why Choose NYBON Machinery for Your Crane Wheel Needs

With years of experience in the industry, NYBON Machinery stands out for:

-

Expertise: Specializing in industrial bridge cranes, gantry cranes, jib cranes, electric hoists, and crane accessories.

-

Quality Assurance: Implementing stringent quality control measures throughout the manufacturing process.

-

Customization: Offering tailored solutions to meet specific client requirements.

-

Global Reach: Serving clients worldwide with reliable and efficient lifting solutions.

Get in Touch with NYBON Machinery

If you’re looking for high-quality crane wheels or other lifting equipment, don’t hesitate to contact us:

-

Email: info@nybonmachinery.com

-

WhatsApp: +86-15936506686

-

Website: www.nyboncrane.com

Let NYBON Machinery be your trusted partner in delivering top-notch lifting solutions tailored to your needs.

Get A Quote Today

Welcome to send a free inquiry to —info@nybonmachinery.com