Calculating Load Capacities for Electric Hoists Accurately

Electric hoists are essential lifting tools in industries ranging from construction to manufacturing. They make heavy lifting easier and safer, but only when used properly. One of the most important aspects of using an electric hoist is understanding its load capacity. Without accurately calculating this, you risk damaging the hoist, the load, or worse, causing an accident. In this article, we’ll break down how to calculate the load capacities of electric hoists accurately, ensuring both safety and efficiency.

What is Load Capacity?

In simple terms, the load capacity of a hoist refers to the maximum weight the hoist can lift safely. This figure is determined by various factors such as the motor power, the lifting mechanism, and the construction of the hoist itself. Knowing the hoist’s load capacity is crucial to ensure that it can safely handle the loads you intend to lift. Exceeding the capacity can lead to hoist failure or safety hazards.

Why Accurate Load Capacity Matters

Knowing your hoist’s accurate load capacity isn’t just about following guidelines—it’s a matter of safety. A hoist that exceeds its weight limit can fail, causing damage to both the hoist and the load. Additionally, overloading can lead to hazardous situations, potentially injuring workers. So, while the load capacity might sound like a technical specification, it’s directly linked to operational safety.

Quick Reference: Electric Hoist Specs Table

| Category | Spec Range | Details | Nybon Standard |

|---|---|---|---|

| Load Capacity | 0.25 – 30 tons | Adjustable for light/heavy lifting | Up to 30 tons, reinforced alloy |

| Lifting Speed | 3 – 25 ft/min | Variable speed options available | 8–20 ft/min (optimized for safety) |

| Power Supply | 110V – 600V, 3-phase | Compatible with global voltages | 220V/380V/480V (customizable) |

| Duty Cycle | 15% – 60% | Standard to heavy-duty operations | 30%–50% (enhanced cooling) |

| Lifting Height | 10 – 100 ft | Wire rope or chain configurations | Up to 80 ft (steel wire rope) |

| Ambient Temp | -20°C to 50°C (-4°F–122°F) | Suitable for harsh environments | -10°C–45°C (standard models) |

| Control Type | Pendant/Remote/RFID | Wireless options for safety & ease | Pendant + RFID (premium models) |

Nybon Machinery’s electric hoists are designed for versatility, combining power, precision, and affordability!

Types of Electric Hoists and Their Capacities

Electric hoists come in different types, each with its specific load capacity depending on the intended application. Some common hoist types include

Wire Rope Hoists, which are typically used for heavier loads and have high capacity ratings.

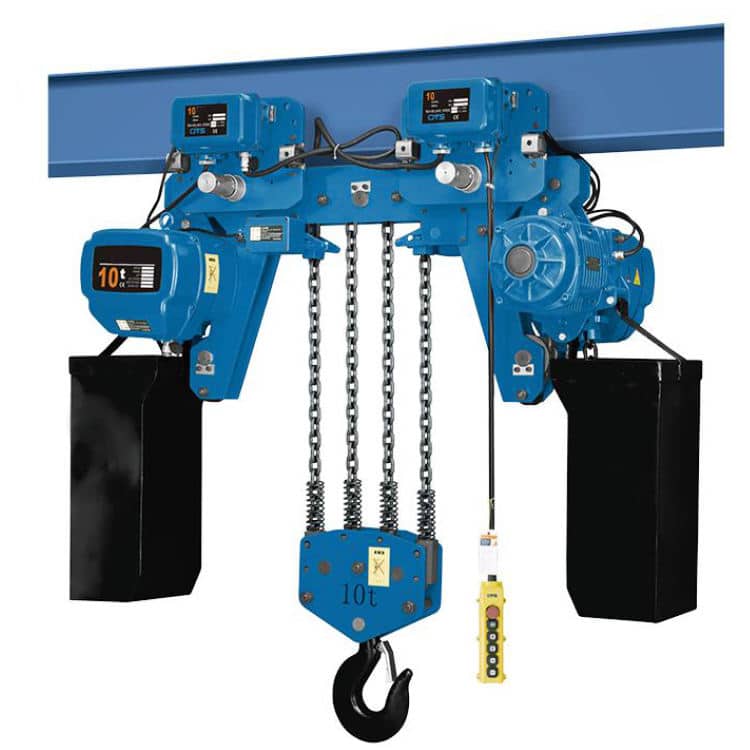

Chain Hoists: Ideal for lighter loads, chain hoists are often used for smaller industrial applications.

Portable Hoists: Designed for mobility, these hoists typically handle lighter capacities.

Overhead Hoists: Built for heavy-duty operations, they often support large industrial machinery. Each type of hoist has its guidelines for load capacity, depending on the mechanism, materials used, and intended use.

Factors That Affect Load Capacity

Several factors come into play when determining a hoist’s load capacity. These are not only technical specifications but also operational conditions that can affect how much weight a hoist can lift safely. Let’s dive deeper into the key factors:

1. Hoist Type and Mechanism

The design of the hoist itself plays a big role in how much weight it can lift. For example, a wire rope hoist is generally more powerful and can handle heavier loads than a chain hoist due to the differences in materials and mechanisms. Each hoist mechanism has a maximum safe load, which should always be considered.

2. Motor Power and Efficiency

The motor’s horsepower and efficiency are key factors that determine the lifting capability. Hoists with larger, more powerful motors can typically handle more weight. However, it’s important to factor in that not all hoists are built to run at full power constantly. Energy efficiency and load balancing are critical here.

3. Rope and Chain Specifications

The type and size of the rope or chain used in the hoist also impact its capacity. Hoists equipped with steel cables can usually lift heavier loads compared to those using chains. Also, the quality and condition of the rope or chain matter. Frayed or worn chains or ropes can significantly lower the hoist’s load capacity.

4. Environment and Conditions

Environmental conditions like temperature, humidity, and exposure to corrosive substances can affect hoist performance. For instance, hoists used in high-humidity environments may experience corrosion, reducing the effective load capacity.

5. Safety and Structural Considerations

A hoist’s overall design and the materials it is made from play a critical role in its load-bearing capacity. Structural integrity, including the quality of the frame and lifting mechanism, ensures the hoist can handle the maximum rated load without failure.

How to Calculate Load Capacity Accurately

Accurately calculating a hoist’s load capacity involves understanding the technical specifications and factors affecting it. Let’s break down the steps for determining the load capacity:

1. Understanding Load Chart Specifications

Every hoist comes with a load chart, which outlines its maximum lifting capacity based on specific conditions. This chart will give you important details such as the hoist’s rated load, the conditions under which it should operate, and safety margins.

2. Calculating Safe Working Load (SWL)

Load testing involves lifting a known weight (typically 125% of the hoist’s rated capacity) to ensure the hoist performs as expected. This is a hands-on verification process that helps confirm the hoist’s load capacity and the accuracy of your calculations. Regular load testing is crucial for ensuring ongoing safety and performance.

3. Load Testing for Verification

The type and size of the rope or chain used in the hoist also impact its capacity. Hoists equipped with steel cables can usually lift heavier loads compared to those using chains. Also, the quality and condition of the rope or chain matter. Frayed or worn chains or ropes can significantly lower the hoist’s load capacity.

Common Mistakes in Load Capacity Calculations

Calculating load capacity might sound straightforward, but many common mistakes can lead to unsafe operations. Some of these include: – Not accounting for environmental conditions: As mentioned earlier, environmental factors can affect the hoist’s capacity, so be sure to factor them in. – Overestimating capacity: Some people mistakenly believe that a hoist can handle more weight than its rated load, which can lead to overloading. – Ignoring safety margins: Always include a safety margin when calculating load capacities.

Best Practices for Ensuring Accurate Load Capacity

To ensure accurate load capacity calculations, follow these best practices: – Always consult the hoist’s load chart. Never assume the hoist’s capacity. Always refer to the manufacturer’s specifications. – Conduct regular load tests: These tests confirm the hoist’s ongoing capacity. – Factor in environmental conditions: Adjust your calculations based on the working environment. – Stay within the rated load: Never exceed the hoist’s maximum capacity.

Accurately calculating the load capacity of electric hoists is essential for maintaining safety and efficiency in your operations. By understanding the factors affecting load capacity, using load charts, and performing regular load testing, you can ensure your hoist performs at its best. Always remember that safety comes first, so take the time to calculate load capacities accurately to prevent accidents and maintain operational integrity.

FAQs

Q1: How do I know if my hoist is overloaded?

A hoist is overloaded if it struggles to lift the load, the motor overheats, or unusual noises occur. Always check the load chart for specifications.

Q2: Can I increase the load capacity of my hoist?

No, you should never try to exceed the rated load capacity. If you need to lift heavier loads, upgrade to a hoist with a higher capacity.

Need a Crane Tailored to YOUR Industry?

At Nybon Group, we’ve built custom cranes and hoists for:

- Ports lifting cargo containers

- Mines hauling ore carts

- Shipyards deploying anchors

Talk to Our Lifting Experts!

📧 Email: info@nybonmachinery.com

📱 WhatsApp: +86-15936506686

🌐 Visit: www.nyboncrane.com

As a professional Industrial Crane Supplier, Nybon offers

- Customizable Solutions – Available in various load capacities, speeds, and configurations to meet specific industrial requirements.

- High-Quality Manufacturing – Built with strict quality standards to ensure durability, reliability, and long service life.

- Low Maintenance Requirements – Engineered for minimal maintenance, reducing downtime and operational costs.

Get A Quote Today

Welcome to send a free inquiry to —info@nybonmachinery.com