Comprehensive Maintenance Checklist for Electric Hoists

Introduction to Electric Hoist Maintenance

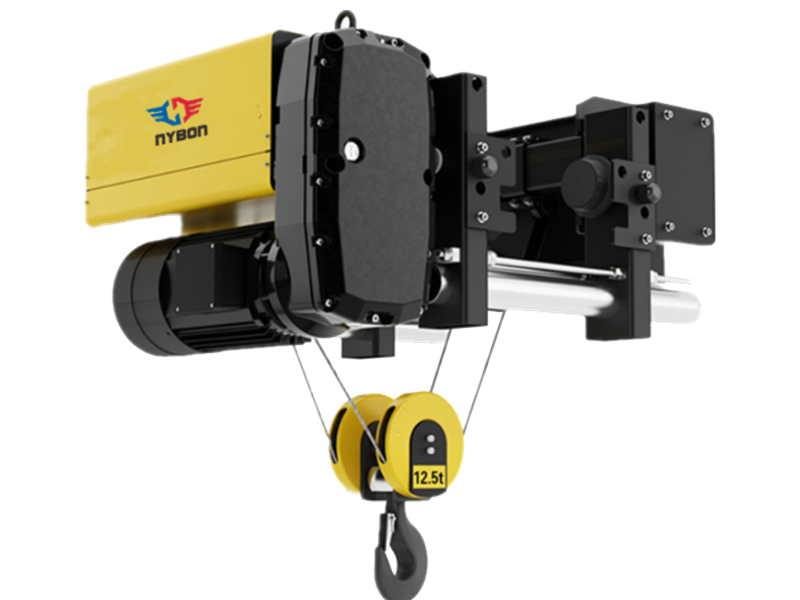

Electric hoists are essential for efficient and safe lifting in various industrial applications. Regular electric hoist maintenance ensures optimal performance, extends the lifespan of the equipment, and prevents costly downtime. At Nybon Machinery, a leading lifting equipment manufacturer producing gantry cranes,overhead cranes,jib cranes.etc, we emphasize the importance of maintaining hoists in peak condition.

In this article, we’ll guide you through a comprehensive checklist for electric hoist maintenance, highlighting key components that require regular inspection and servicing.

Key Components to Inspect in Electric Hoists

1. Chain and Rope

-

Inspect the chain or rope for signs of wear, fraying, or damage.

-

Check for any kinks, twists, or broken links.

-

Lubricate the chain to reduce friction and prevent premature wear.

-

Ensure the rope is running smoothly through the sheave and there is no slack.

2. Electric Motor

-

Check for unusual noises or overheating during operation.

-

Inspect the motor’s wiring for any loose or damaged connections.

-

Ensure that the motor is clean and free of debris that could hinder airflow.

-

Verify that the motor’s insulation is intact.

3. Braking System

-

Test the brakes to ensure they are functioning properly, preventing the load from slipping.

-

Check for wear on brake pads or friction materials.

-

Inspect the brake mechanism for any signs of corrosion or rust.

Faster global action than our competitors

More trusted customers worldwide.

Regular Inspection Tasks for Hoist Maintenance

1. Daily Inspections

-

Before each shift, check the hoist’s load capacity and ensure it is within the limits.

-

Look for signs of wear or damage on hooks, load chains, and ropes.

-

Ensure that all buttons, controls, and safety mechanisms are working correctly.

2. Monthly Inspections

-

Lubricate moving parts, including the chain and motor components.

-

Check the hoist’s electrical components, including wiring and connectors.

-

Inspect the hoist’s alignment to ensure it is not misaligned.

3. Annual Inspections

-

Conduct a thorough inspection of the entire hoist system.

-

Perform load testing to ensure the hoist is operating within its rated capacity.

-

Replace worn-out parts, such as chains, brakes, or motors, as necessary.

Best Practices for Electric Hoist Maintenance

1. Lubrication

-

Regular lubrication is essential to reduce wear and tear on moving parts, especially the chains and gears. Use the recommended lubricants to maintain smooth operation.

2. Cleaning

-

Dust, dirt, and debris can affect the performance of your hoist. Ensure that all components, especially the motor and chain, are kept clean and free from contaminants.

3. Follow Manufacturer Guidelines

-

Always adhere to the manufacturer’s maintenance schedule and guidelines. This ensures that all maintenance tasks are performed at the right intervals, preventing unnecessary repairs.

Electric Hoist Specs

| Parameter | Range |

|---|---|

| Capacity | 0.25 to 100 tons |

| Lifting Height | 3-50m |

| Speed | Single/Double Speed |

| Power | 110V-480V,50-60hz |

| Applications | Work independently or work together with single-beam/double-beam cranes |

Troubleshooting Common Electric Hoist Issues

1. Hoist Not Lifting

-

Possible Cause: Insufficient power supply or a faulty motor.

-

Solution: Check the electrical supply, inspect the motor, and verify wiring connections.

2. Slow or Jerky Operation

-

Possible Cause: Worn-out gears or insufficient lubrication.

-

Solution: Lubricate the hoist components and check the gears for signs of wear.

3. Unusual Noises

-

Possible Cause: Worn bearings or debris inside the motor.

-

Solution: Clean the motor and replace any worn-out bearings.

Electric hoist maintenance is crucial for ensuring safety, efficiency, and longevity. By following a structured maintenance checklist and performing regular inspections, you can prevent costly repairs and improve the reliability of your equipment. At Nybon Machinery, we prioritize quality and durability in all our lifting equipment, and we recommend that all users adopt proactive maintenance practices.

Get A Quote Today

Welcome to send a free inquiry to —info@nybonmachinery.com