Crane Beam, Main Girder & End Carriage for Cranes | NYBON

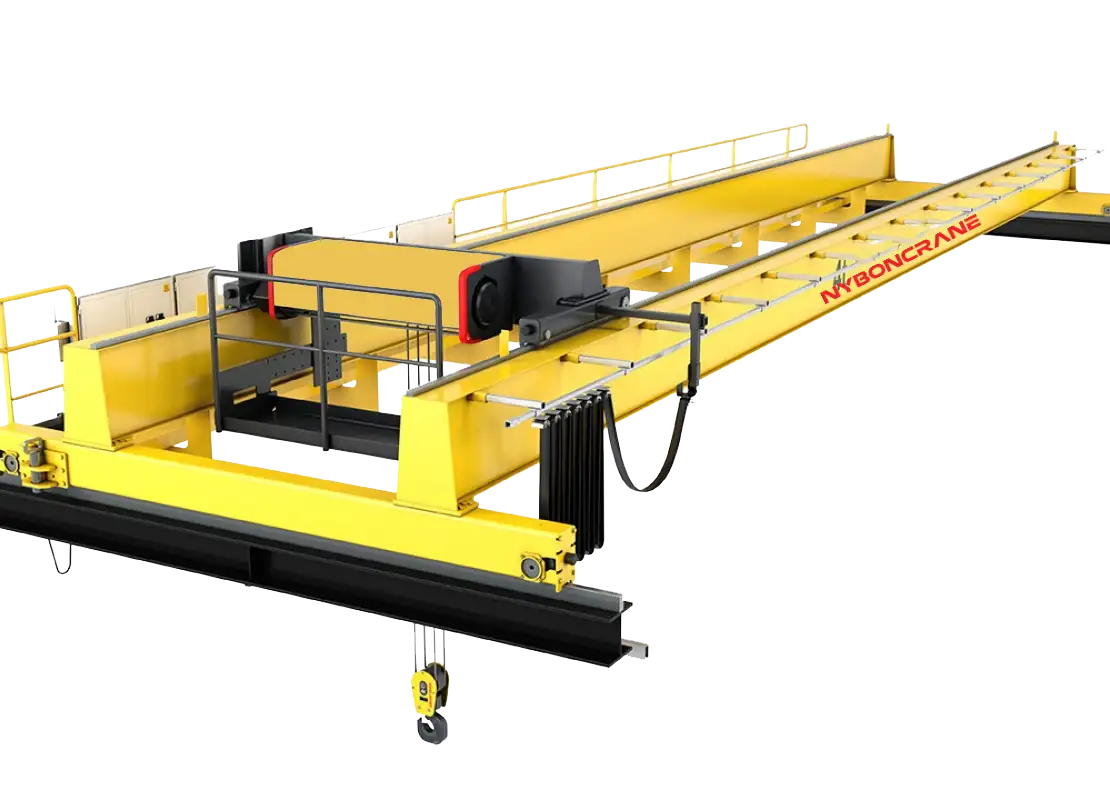

NYBON supplies crane beams including main girders and crane end carriages for overhead and gantry cranes. Custom designs available.

Rich Experience

OEM Supported

Various Solutions

For your project

24/7 Support

R&D Team standing by

Key Advantages of NYBON Crane Beams

High structural strength and optimized load distribution

Precision fabrication for accurate installation

Compatible with various crane wheel and drive systems

Long service life under continuous operation

Flexible design for standard and custom cranes

Applications

NYBON crane beams are widely used in different industrial lifting environments:

Manufacturing workshops

Steel plants and foundries

Warehouses and logistics centers

Power plants and heavy industry facilities

Port and shipyard crane systems

Key Advantages of NYBON Crane Beams

Crane beams work together with other crane components to form a complete lifting system. NYBON main girders and end carriages can be integrated with crane wheels, hoist trolleys, electric hoists, and control systems.

This modular compatibility allows easy installation, maintenance, and future upgrades.

Key Advantages of NYBON Crane Beams

NYBON provides custom crane beam solutions based on project requirements. Customization options include span length, lifting capacity, structural design, and surface treatment.

Whether for standard industrial cranes or special lifting applications, NYBON’s engineering team delivers tailored beam designs to meet specific working conditions.

Why Choose NYBON Crane Beams

Professional crane structure manufacturing experience

High-quality steel materials and strict welding control

Custom design for different crane systems

Reliable performance for heavy-duty applications

Complete technical support from design to delivery

Crane Types Using End Carriages

The specific application often dictates the type of crane the end carriage is attached to:

Single Girder Overhead Cranes: For lighter, more compact workshop needs.

Double Girder Overhead Cranes: For heavy-duty lifting and wider spans.

Gantry Cranes: Used in outdoor yards where overhead runways aren’t available.

Semi-Gantry Cranes: Often used indoors along one wall to save floor space.

Send Us A Message