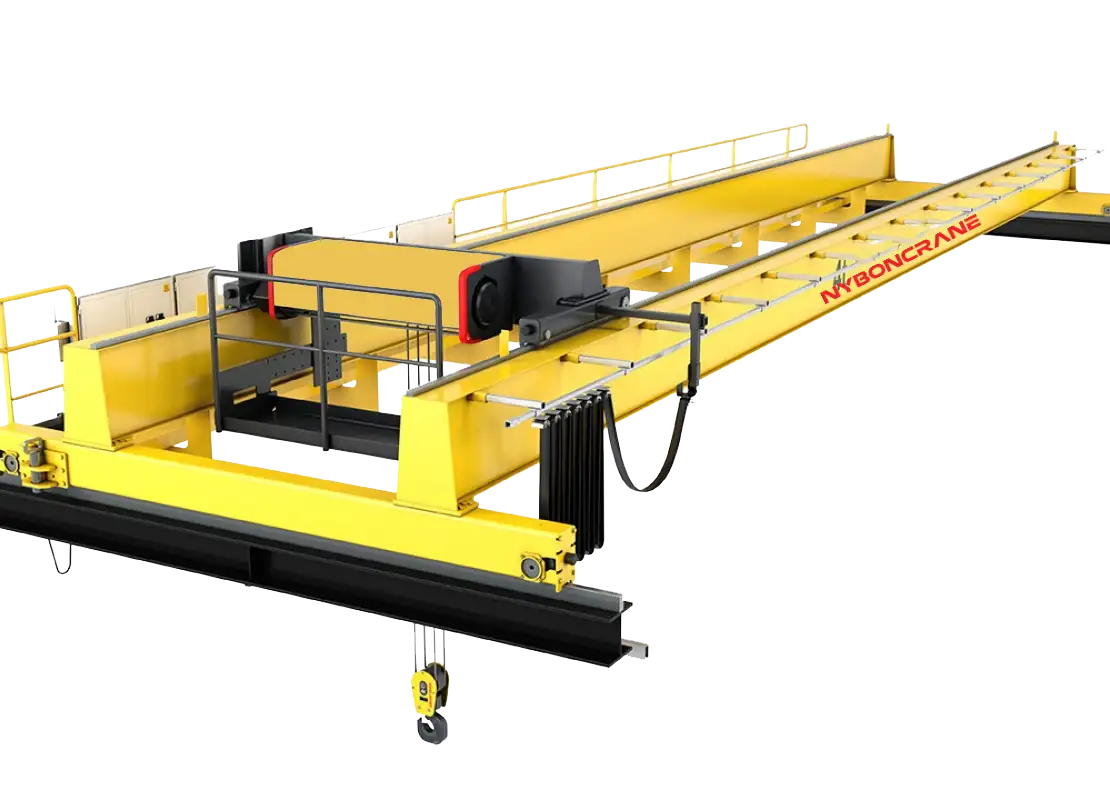

Crane Wheel & Crane Wheel Assembly Manufacturer | NYBON

High-Performance Steel Wheels for Industrial Cranes and Carts

Rich Experience

OEM Supported

Various Solutions

For your project

24/7 Support

R&D Team standing by

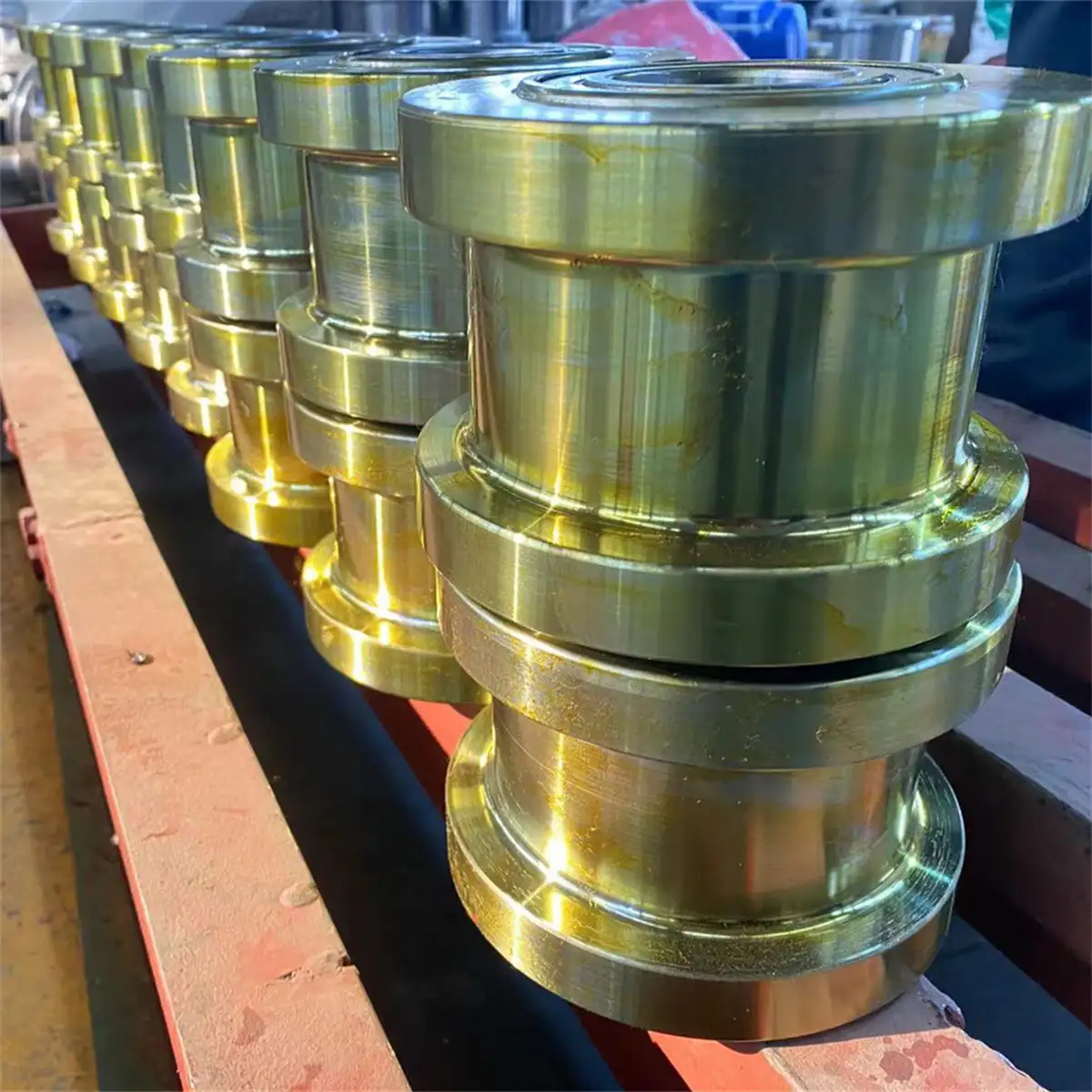

Single Flange Crane Wheel

Single flange crane wheels are commonly used in standard crane travel systems. The flange helps guide the wheel along the rail while allowing stable and smooth motion.This type is widely applied in overhead cranes and light to medium-duty gantry cranes.

Double Flange Crane Wheel

Double flange crane wheels provide enhanced lateral stability and are suitable for applications with higher side forces or uneven working conditions.

They are often used in heavy-duty gantry cranes and rail-mounted transfer carts.

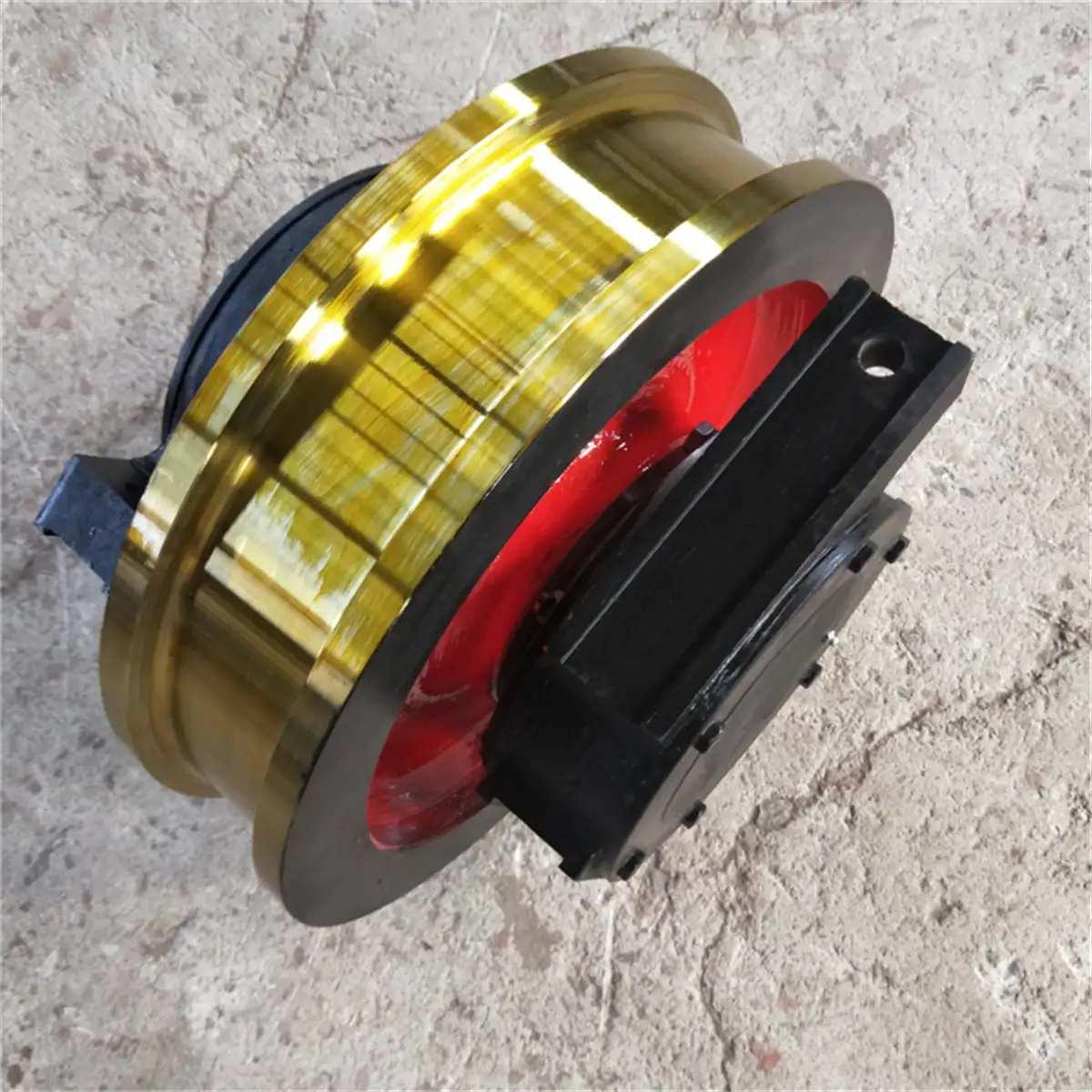

Crane Wheel Assembly

A crane wheel assembly integrates the wheel, axle, bearing, and bearing housing into a complete unit. Compared with standalone wheels, assemblies offer higher installation accuracy, better load distribution, and easier maintenance.

NYBON supplies wheel assemblies for crane end carriages, hoist trolleys, and industrial transport systems.

DRS Wheel Block System

DRS wheel blocks are modular wheel units widely used in modern crane and transfer systems. Each DRS wheel block integrates the wheel, bearings, housing, and mounting interface into a compact structure, allowing flexible installation and alignment.DRS wheel blocks are especially suitable for overhead cranes, gantry cranes, transfer carts, and special industrial equipment where modular design and easy replacement are required. NYBON provides DRS-type wheel blocks in various sizes, load capacities, and configurations.

Equipment Compatibility

NYBON crane wheels and DRS wheel blocks are designed to integrate seamlessly with different equipment structures. They are commonly installed on crane bridges, gantry crane legs, crane trolleys, and industrial transfer platforms.

Our wheel systems are also suitable for customized heavy equipment that requires reliable rail travel and high load-bearing performance.

Key Advantages of NYBON Crane Wheels

High load capacity for heavy-duty crane operations

Excellent wear resistance and impact strength

Precision machining for smooth and stable rail travel

Modular options including DRS wheel block systems

Long service life under continuous working conditions

Applications of Crane Wheels

Crane wheels are not limited to traditional crane systems. NYBON metal wheels and wheel assemblies are widely used in various heavy-duty and rail-guided equipment, including:

Overhead cranes and gantry cranes

Crane end carriages and hoist trolleys

Rail transfer carts and material transport vehicles

Automated guided transfer systems (AGV-based carts)

Heavy industrial equipment and port machinery

This wide application range allows NYBON crane wheels to meet both lifting and horizontal transport requirements.

Why Choose NYBON Crane Wheels

In-house manufacturing with strict quality control

Full range from single wheels to DRS wheel blocks

Proven performance in crane and transfer cart systems

Flexible customization for special applications

Professional engineering support for project solutions

Send Us A Message