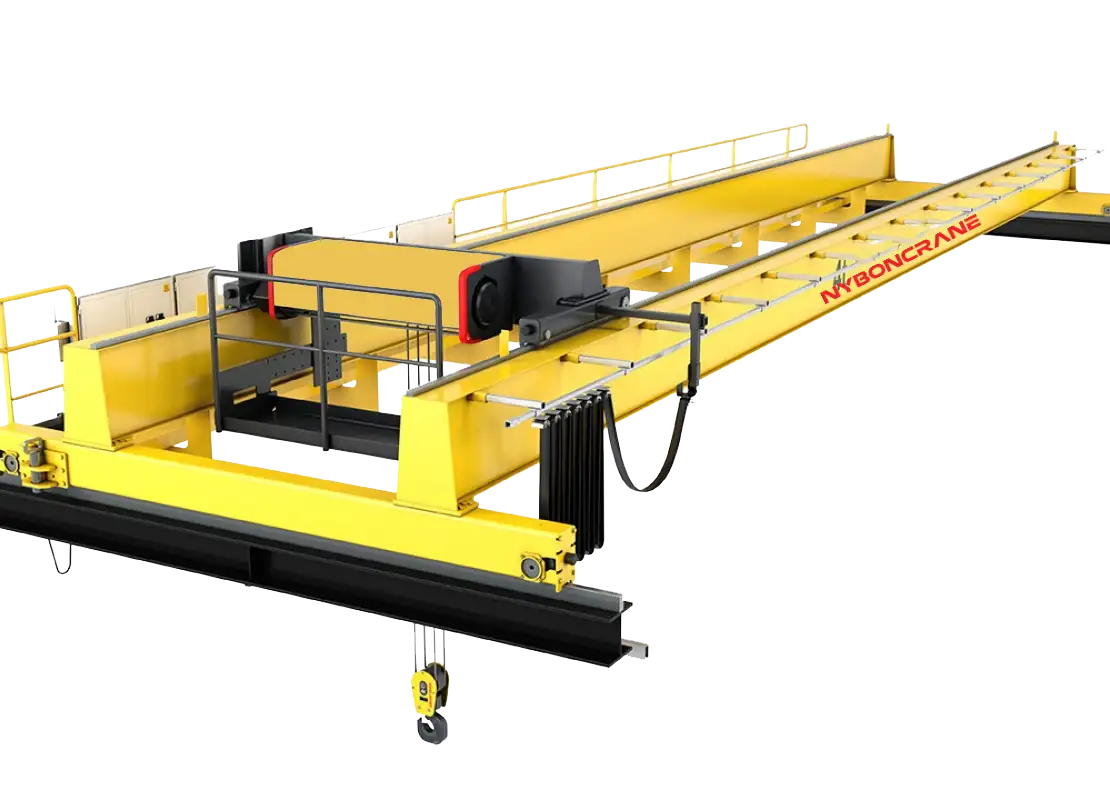

Double Girder Overhead Crane

We inspire our customers & support local businesses

Rich Experience

OEM Supported

Various Solutions

For your project

24/7 Support

R&D Team standing by

Types of Double Girder Overhead Cranes

Key Features of NYBON Double Girder Overhead Cranes

Strong double-girder design for maximum stability

High lifting capacity: up to 500 tons

Heavy-duty trolley winch for continuous 24/7 operation

Smooth and reliable frequency inverter control

Robust steel structure with long service life

Precise positioning and safe operation

Customizable lifting height, span, and working class

Applications of Double Girder Overhead Cranes

Steel production and metallurgy

Large machinery manufacturing

Mining and heavy industrial workshops

Power plants and hydropower stations

Chemical and energy industries

Equipment assembly lines

Container and material transfer stations

Why Choose NYBON Machinery?

Professional heavy-duty crane manufacturer

Advanced production line & strict quality control

Full engineering selection and design support

Custom solutions for unique lifting environments

Fast delivery and long-term after-sales service

Send Us A Message