Electric Hoists: The Ultimate Solution for Efficient and Reliable Lifting Operations

Electric hoists are an essential part of industrial lifting and material handling systems, offering unmatched convenience, efficiency, and safety for various applications. In this comprehensive guide, we will explore the key features, benefits, and types of electric hoists, helping you make an informed decision on the best equipment for your specific needs.

What is an Electric Hoist?

An electric hoist is a mechanical device powered by electricity, designed to lift and lower heavy loads with precision and ease. Typically mounted on overhead cranes or as standalone units, electric hoists are ideal for industrial, construction, and warehouse settings where heavy lifting is a routine task. These hoists utilize electric motors to drive the lifting mechanism, providing an efficient and reliable means of handling heavy materials.

Key Features of Electric Hoists

1. High Load Capacity

Electric hoists are designed to handle a wide range of load capacities, making them suitable for various applications. From small, light-duty tasks to heavy-duty industrial lifting, there is an electric hoist tailored to meet your specific requirements. Common capacities range from 500 kg to several tons, with customization options available.

2. Precise Control and Speed

With variable speed control, electric hoists allow for smooth and precise load movements. Operators can adjust the lifting speed based on the nature of the task, ensuring safety and accuracy. Whether you need to lift materials slowly for delicate handling or quickly for large-scale operations, an electric hoist provides the necessary flexibility.

3. Durability and Longevity

Built to withstand harsh industrial environments, electric hoists are made from high-quality materials that ensure long-lasting durability. They are resistant to corrosion, wear, and tear, offering reliable performance even in the most challenging conditions. Regular maintenance can further extend the lifespan of the hoist, reducing downtime and repair costs.

4. Safety Features

Safety is paramount in any lifting operation, and electric hoists are equipped with several features to protect both the operator and the load. These features typically include:

-

Overload protection to prevent excessive strain on the hoist

-

Limit switches to avoid over-traveling

-

Emergency stop buttons for quick halts in case of a malfunction

-

Anti-sway mechanisms for stability during lifting

5. Compact and Space-Saving Design

Electric hoists are available in both compact and low-headroom designs, which allow them to be used in tight spaces with limited vertical clearance. These models are perfect for applications where space is at a premium but high lifting capacity is still required.

Types of Electric Hoists

Electric hoists come in various configurations, each designed for specific tasks and applications. Below are the most common types:

1. Wire Rope Hoists

Wire rope hoists are widely used in heavy-duty industrial applications. They feature a steel wire rope that winds around a drum, allowing the hoist to lift and lower loads. These hoists are ideal for lifting heavier loads at greater heights and can be used in conjunction with overhead cranes for enhanced performance.

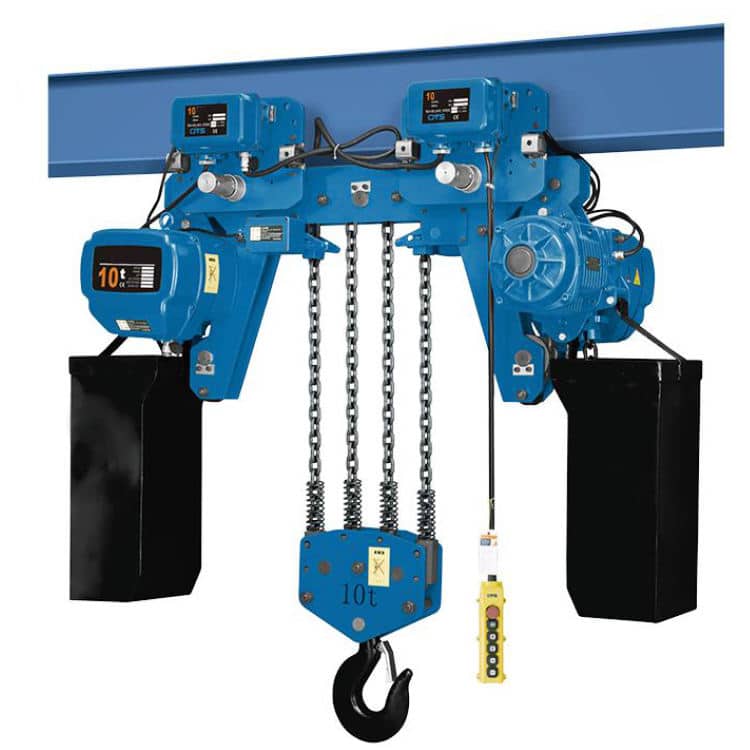

2. Chain Hoists

Chain hoists are typically used for lighter loads compared to wire rope hoists. They are designed with a chain that is reeled in or out to lift or lower materials. Chain hoists are particularly useful for precision lifting tasks in confined spaces and are often used in workshops, warehouses, and light industrial applications.

3. Monorail Hoists

Monorail hoists are mounted on a single rail system, allowing them to move along the rail in a straight line. These hoists are commonly used in assembly lines or warehouses where a single line of lifting is required. They can also be integrated with automated material handling systems for increased productivity.

4. Explosion-Proof Hoists

For applications involving hazardous materials or environments where flammable gases are present, explosion-proof electric hoists are essential. These hoists are built with special enclosures to prevent ignition of sparks and are used in industries such as oil, gas, and chemicals.

Quick Reference: Electric Hoist Specs Table

| Category | Spec Range | Details | Nybon Standard |

|---|---|---|---|

| Load Capacity | 0.25 – 30 tons | Adjustable for light/heavy lifting | Up to 30 tons, reinforced alloy |

| Lifting Speed | 3 – 25 ft/min | Variable speed options available | 8–20 ft/min (optimized for safety) |

| Power Supply | 110V – 600V, 3-phase | Compatible with global voltages | 220V/380V/480V (customizable) |

| Duty Cycle | 15% – 60% | Standard to heavy-duty operations | 30%–50% (enhanced cooling) |

| Lifting Height | 10 – 100 ft | Wire rope or chain configurations | Up to 80 ft (steel wire rope) |

| Ambient Temp | -20°C to 50°C (-4°F–122°F) | Suitable for harsh environments | -10°C–45°C (standard models) |

| Control Type | Pendant/Remote/RFID | Wireless options for safety & ease | Pendant + RFID (premium models) |

Nybon Machinery’s electric hoists are designed for versatility, combining power, precision, and affordability!

Benefits of Using Electric Hoists

1. Increased Efficiency

Electric hoists significantly reduce the manual effort required for lifting and moving heavy loads. By automating the process, these hoists enhance productivity, allowing employees to focus on other tasks while the hoist handles the lifting duties.

2. Improved Safety

Electric hoists are equipped with various safety features, such as overload protection and emergency stops, ensuring that operations remain secure. These safety features help reduce the risk of accidents and injuries, making electric hoists a safer alternative to manual lifting methods.

3. Cost-Effectiveness

Though the initial investment in an electric hoist may be higher than manual alternatives, the long-term savings are considerable. Electric hoists require less manpower, reduce the risk of injuries, and can operate continuously for extended periods with minimal downtime.

4. Versatility

Electric hoists can be used in a wide range of industries, including construction, manufacturing, logistics, and more. Whether you need to lift heavy equipment, move materials, or position machinery, there is an electric hoist designed for your needs.

Choosing the Right Electric Hoist

When selecting an electric hoist, several factors must be considered to ensure you choose the best option for your application. Here are the key points to keep in mind:

1. Load Capacity

The load capacity of the hoist should match the weight of the materials you plan to lift. Always choose a hoist with a capacity higher than your heaviest load to ensure safe and efficient operation.

2. Lifting Height

Consider the maximum lifting height you require for your operations. Electric hoists come in various models with different lifting heights, so choose one that meets your operational needs.

3. Speed Control

If your operations require precise control over the speed of lifting and lowering, choose a hoist with variable speed options. This allows operators to adjust the lifting speed based on the specific task at hand.

4. Environment

Evaluate the environment in which the hoist will be used. If you’re working in a harsh or hazardous environment, consider explosion-proof models or those built for outdoor use, where weather conditions might be a factor.

5. Maintenance Needs

Regular maintenance is essential for ensuring the longevity and optimal performance of electric hoists. Choose a hoist from a manufacturer that offers reliable customer support and maintenance services.

Electric Hoists in Action: Industry Applications

1. Construction

In the construction industry, electric hoists are used to lift building materials, tools, and equipment to higher floors. They can handle heavy loads like steel beams, cement blocks, and machinery, improving the efficiency of the construction process.

2. Warehousing and Logistics

In warehouses, electric hoists are used to lift pallets, containers, and other goods, reducing the manual labor required in material handling. Monorail hoists and chain hoists are particularly common in these environments.

3. Manufacturing

Electric hoists are integral to manufacturing lines where heavy machinery and parts need to be lifted or positioned with precision. These hoists are used to move large components, such as engine blocks or machinery parts, in and out of assembly lines.

4. Marine and Offshore

In marine environments, electric hoists are used to lift heavy cargo, equipment, and supplies on and off ships or platforms. Special marine hoists are designed to withstand corrosive saltwater conditions and offer reliable performance in offshore operations.

Maintenance and Safety Tips for Electric Hoists

1. Inspect Load Limiters and Safety Features

Regularly check the overload protection, limit switches, and emergency stop mechanisms to ensure they are functioning correctly.

2. Lubricate Moving Parts

Proper lubrication of moving components, such as the gears and chain, helps reduce friction and wear, extending the hoist’s lifespan.

3. Check for Wire or Chain Wear

Inspect the wire rope or chain for signs of wear or damage. Replace any worn or frayed sections to prevent accidents.

4. Test the Hoist Periodically

Run periodic tests to check for any malfunctions. Ensuring the hoist is operating smoothly prevents costly repairs and unexpected downtime.

Electric hoists are a critical component in modern material handling systems, offering unmatched efficiency, safety, and versatility for a variety of industrial applications. Whether you need to lift light loads or heavy machinery, there is a solution available that can meet your specific requirements. By selecting the right electric hoist and maintaining it properly, you can enhance the productivity of your operations while ensuring the safety of your staff.

Need a Crane Tailored to YOUR Industry?

At Nybon Group, we’ve built custom cranes and hoists for:

- Ports lifting cargo containers

- Mines hauling ore carts

- Shipyards deploying anchors

Talk to Our Lifting Experts!

📧 Email: info@nybonmachinery.com

📱 WhatsApp: +86-15936506686

🌐 Visit: www.nyboncrane.com

As a professional Industrial Crane Supplier, Nybon offers

- Customizable Solutions – Available in various load capacities, speeds, and configurations to meet specific industrial requirements.

- High-Quality Manufacturing – Built with strict quality standards to ensure durability, reliability, and long service life.

- Low Maintenance Requirements – Engineered for minimal maintenance, reducing downtime and operational costs.

Get A Quote Today

Welcome to send a free inquiry to —info@nybonmachinery.com