How to Choose the Right Industrial Crane for Your Workshop or Factory

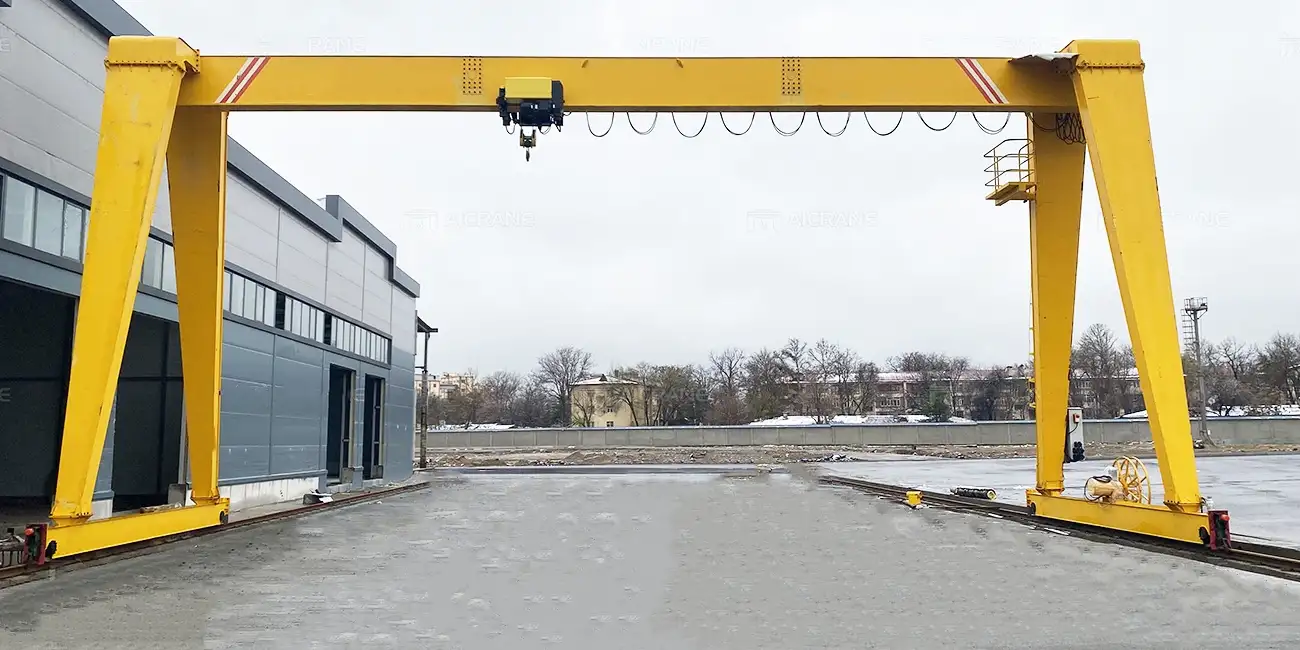

An industrial gantry crane is one of the most practical lifting solutions for factories and material handling yards that require flexibility, high load capacity, and reliable outdoor or semi-outdoor operation.

Unlike building-supported cranes, gantry cranes operate on ground rails or wheels, making them ideal for facilities where structural support is limited or lifting areas need to remain open and adaptable.

What Is an Industrial Gantry Crane?

An industrial gantry crane is a type of crane supported by legs that move along ground-mounted rails or wheels. It is designed to handle heavy loads while offering a wide working range and simple installation.

Because it does not rely on building columns, this crane type is widely used in open workshops, yards, and temporary lifting areas.

Key Applications of Industrial Gantry Cranes

Manufacturing Plants

In manufacturing facilities, industrial gantry cranes are used to move heavy components between production stages. They support efficient material flow while reducing manual handling risks.Typical uses include: Moving steel structures; Handling large machine parts; Assembly support

Steel and Metal Processing

Steel fabrication yards often require lifting equipment that can operate outdoors and handle irregular loads. An industrial gantry crane provides stable lifting performance in harsh environments.

Warehouses and Material Yards

For open storage areas, gantry cranes enable fast loading and unloading of long or heavy materials such as pipes, beams, and coils. We also have crane parts.

Infrastructure and Construction Support

Industrial gantry cranes are commonly used in precast concrete yards and infrastructure projects, where mobility and lifting capacity are essential.

Standard Technical Parameters (Customizable)

| Item | Typical Range |

|---|---|

| Lifting Capacity | 1 – 200 tons |

| Span | Up to 40 meters |

| Lifting Height | Up to 30 meters |

| Working Duty | A3 – A7 |

| Power Supply | 380V / 50Hz (Customizable) |

| Operation Mode | Rail-mounted / Rubber wheel |

| Control Method | Pendant / Remote Control / Cabin |

✅ All parameters support customization based on project requirements.

Advantages of Using an Industrial Gantry Crane

Flexible Installation-No building support is required, which significantly reduces installation constraints and costs.

High Load Capacity-Industrial gantry cranes are suitable for light-duty to heavy-duty lifting tasks, depending on design and configuration.

Outdoor and Indoor Compatibility-They can be designed for both indoor workshops and outdoor yards.

Customization Options for Industrial Gantry Cranes

Every application has different load sizes, lifting frequencies, and site conditions. A customized industrial gantry crane can include:

Non-standard span and height

Special lifting speed

Outdoor protection design

Integrated safety systems

At Nybon Machinery, industrial gantry cranes are designed and manufactured based on real operating conditions to ensure long-term reliability.

Frequently Asked Questions (FAQ)

Q1: Where is an industrial gantry crane commonly used?

It is widely used in manufacturing plants, steel yards, warehouses, and construction-related material handling areas.

Q2: Can an industrial gantry crane be used outdoors?

Yes. Industrial gantry cranes are suitable for outdoor use with proper design and protection measures.

Q3: Is customization available for industrial gantry cranes?

Yes. Load capacity, span, height, control method, and operating mode can all be customized.

Q4: What lifting capacities are available?

Industrial gantry cranes typically range from 1 ton to 200 tons, depending on design and electric hoist.

Q5: Does Nybon Machinery provide complete gantry crane systems?

Yes. Nybon Machinery provides complete industrial gantry crane solutions, including design, manufacturing, and crane components.