How to Choose the Right Industrial Crane for Your Workshop or Factory

Choosing the right industrial crane is a critical decision for factories, warehouses, and workshops involved in lifting and material handling. A well-selected crane improves efficiency, safety, and long-term operating costs.

In this guide, we explain the most common types of industrial cranes, key technical factors to consider, and how customized crane solutions can better match your actual working conditions.

Common Types of Industrial Cranes

An overhead crane is widely used in factories, steel workshops, and production lines. It runs on rails installed on building columns and is ideal for indoor lifting operations with high frequency and heavy loads.

Typical applications:

Manufacturing workshops

Assembly lines

Heavy equipment production

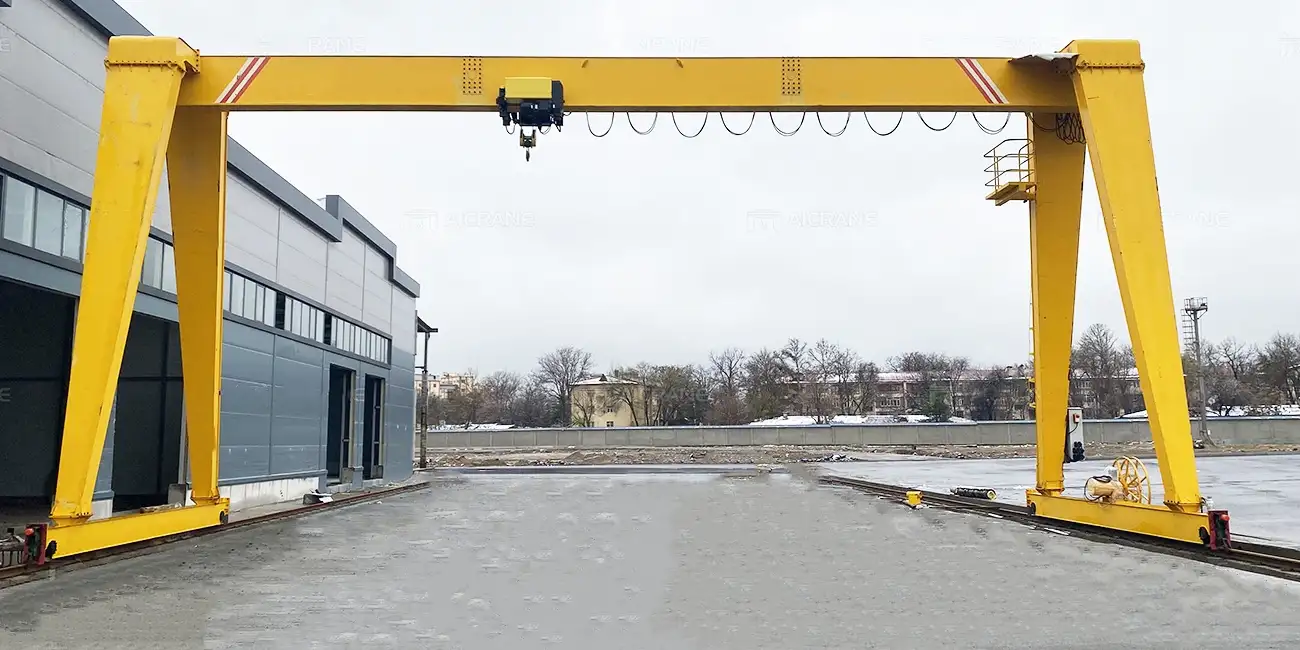

A gantry crane is supported by ground rails and does not rely on building structures. It is suitable for outdoor yards, open warehouses, and large-span lifting operations.

Typical applications:

Precast yards

Container handling

Steel structure yards

A jib crane is a compact lifting solution for localized workstations. It is often used as a supplementary crane for precise and repetitive lifting tasks.

Typical applications:

Workstations

Maintenance areas

Light-duty workshops

An electric hoist is the core lifting unit of many cranes. It can be used independently or integrated with overhead cranes and gantry cranes.

Typical applications:

Small workshops

Production lines

Crane upgrades

Key Factors to Consider When Choosing an Industrial Crane

Lifting Capacity

The rated lifting capacity should be higher than the maximum load to ensure safe operation and long service life.

Span and Lifting Height

Span and lifting height must match your workshop size, layout, and material handling process.

Working Environment

Indoor or outdoor use, temperature, humidity, and dust conditions all affect crane design and component selection.

Duty Class and Working Frequency

High-frequency operations require cranes designed for heavier duty classes to reduce maintenance costs.

Standard Technical Parameters (Customizable)

| Item | Typical Range |

|---|---|

| Lifting Capacity | 0.5 – 200 tons |

| Span | Up to 40 meters |

| Lifting Height | Up to 30 meters |

| Working Duty | A3 – A7 |

| Power Supply | 380V / 50Hz (Customizable) |

| Control Method | Pendant / Remote Control / Cabin |

✅ All parameters support customization based on project requirements.

Why Customization Matters for Industrial Cranes

Every factory has different layouts, lifting processes, and safety requirements. A customized crane solution can:

Improve lifting efficiency

Reduce installation cost

Extend equipment service life

At Nybon Machinery, we provide custom-designed industrial cranes and lifting equipment based on actual working conditions, drawings, and customer specifications.

Frequently Asked Questions (FAQ)

What is the difference between a gantry crane and an overhead crane?

An overhead crane runs on building-mounted rails, while a gantry crane is supported by ground rails and does not rely on the building structure.

Can industrial cranes be customized?

Yes. Lifting capacity, span, lifting height, control method, and power supply can all be customized.

How do I choose the right crane capacity?

The crane capacity should be selected based on the maximum load plus an appropriate safety margin.

Are electric hoists suitable for independent use?

Yes. Electric hoists can be used independently or integrated into crane systems.

Does Nybon Machinery provide complete crane solutions?

Yes. Nybon Machinery provides complete industrial crane systems, including design, manufacturing, and customized crane components.