Semi Gantry Crane vs. Full Gantry Crane: Top 5 Differences

Choosing the right lifting equipment can significantly optimize your workplace efficiency. While both full and semi-gantry cranes are powerful tools, their structural designs serve different operational needs.Want to learn about single vs. double girder designs? Check our previous Gantry Crane Guide.

1. Structural Design and Support

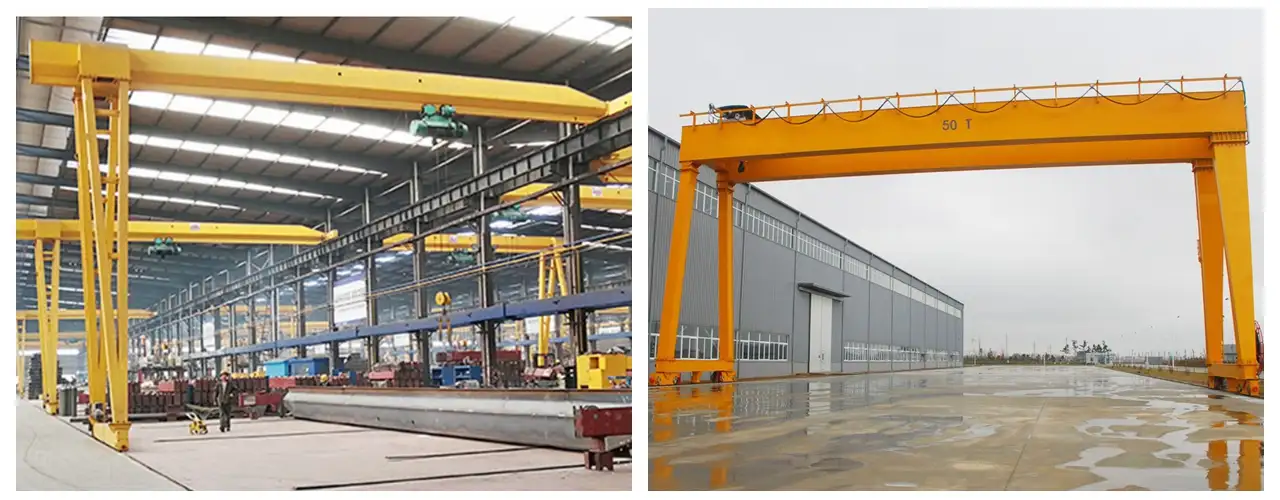

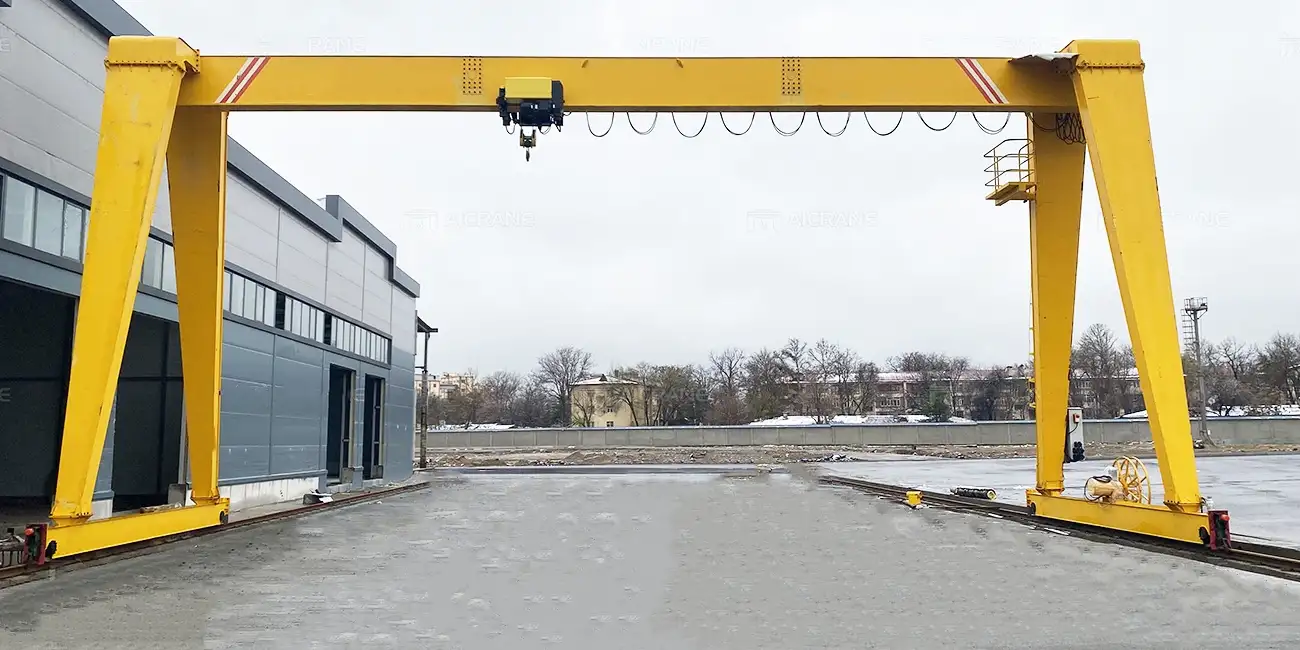

The primary difference lies in the support structure. A full gantry crane is a type of overhead crane with two freestanding legs that move along a track. A semi-gantry crane, however, is designed with one side supported by legs while the other side rests on a wall or building structure.

2. Space Utilization

Semi-gantry cranes are ideal for narrow workshops. Because they use the building structure as one support, they significantly reduce floor space usage compared to full gantries. They help preserve headroom and floor space under the fixed side.

3. Cost-Effectiveness

If you are working with a tight budget, the semi-gantry model is often more attractive. It offers lower initial investment and maintenance costs because it requires fewer legs and shorter rails.

4. Installation and Layout Flexibility

Semi-gantry cranes offer greater flexibility for changing site layouts. They are often easier to install or relocate due to their modular design. Full gantry cranes, while providing maximum lifting capacity and operational freedom, require a more permanent and spacious setup.

5. Application Scenarios

Full Gantry: Best for open yards, shipyards, and heavy-duty lifting.

Semi-Gantry: Perfect for indoor work cells, especially when installed under existing overhead cranes.

Explore Nybon’s high-performance Electric Hoists for your next project.

📊 Technical Comparison Table

| Feature | Full Gantry Crane | Semi-Gantry Crane |

|---|---|---|

| Leg Configuration | Two independent legs | One leg + One wall/structure support |

| Space Usage | High (Requires both sides clear) | Low (Saves space against walls) |

| Initial Cost | Higher | Lower (Budget-friendly) |

| Maintenance | Higher maintenance points | Lower overall maintenance |

| Common Use | Outdoor yards, Rail yards | Indoor workshops, Small warehouses |

Lifting equipment we produce

Gantry cranes

Overhead cranes

Jib Cranes

- KBK Modular Cranes

- Electric Hoists

- Crane Parts.etc

Conclusion: Making Your Choice with Nybon Crane

At the end of the day, the best crane is the one that keeps your production moving safely and efficiently. Whether you need a simple single girder setup or a massive double girder system, Nybon Crane is here to help with custom engineering and reliable manufacturing.

Need a custom gantry crane solution for your project? Contact Nybon Crane Experts today for a free quote!

Frequently Asked Questions

1. Is a semi-gantry crane safer than a full gantry?

Both are equally safe when manufactured by Nybon Crane. Safety depends on proper installation and choosing the right duty class for your operations.

2. Can a semi-gantry crane be installed outdoors?

Yes, but they are most effective indoors where they can utilize the existing building structure for support.

3. Does the semi-gantry save a lot of space?

Yes! By mounting one side to the wall, you eliminate a ground track and leg, freeing up over 1 meter of floor space in narrow aisles.

4. Why choose a full gantry for heavy loads?

Full gantry cranes offer maximum lifting capacity and stability for extreme heavy-duty lifting in open areas.

5. Can I use a semi-gantry under an overhead crane?

Absolutely. Semi-gantries are frequently installed under larger overhead cranes to handle localized lifting tasks in a specific work area.