everything you need to know about ladle cranes

Steel Mill Crane: Comprehensive Guide to Heavy-Duty Lifting Solutions

Steel mill cranes are an integral part of the steel manufacturing process, designed to handle the challenging environments and heavy loads encountered in steel production facilities. These robust machines ensure the efficient and safe transportation of materials such as molten metal, steel coils, and finished products. By optimizing productivity and reducing downtime, steel mill cranes are indispensable in modern steel mills.

Content Index

- Types of Steel Mill Cranes

- Features and Specifications of Steel Mill Cranes

- Applications in the Steel Industry

- Safety and Maintenance Best Practices

- Benefits of Steel Mill Cranes

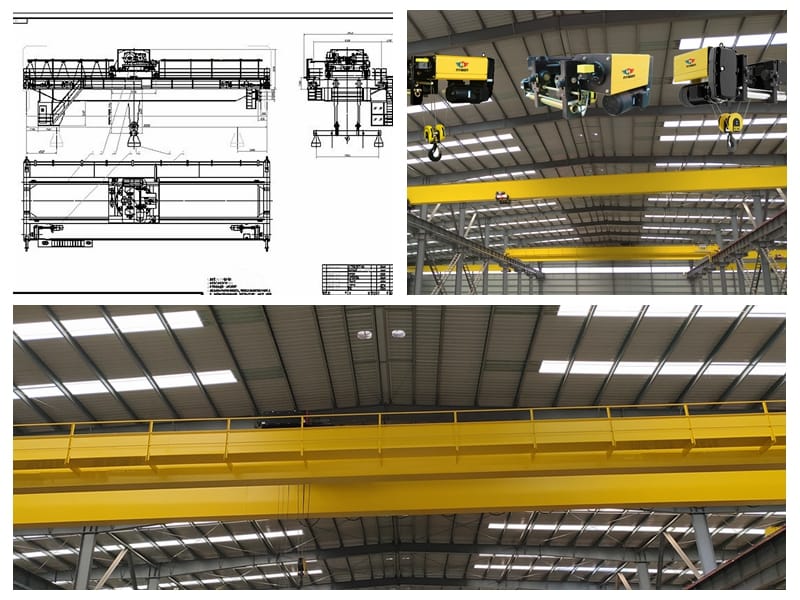

Types of Steel Mill Cranes

Steel mill cranes come in various designs tailored to specific tasks within the steel production process. The most common types include:

- Ladle Cranes: Used for transporting molten steel, these cranes feature heat-resistant components to withstand extreme temperatures.

- Billet and Slab Handling Cranes: Designed to move semi-finished products such as billets and slabs efficiently.

- Coil Handling Cranes: Ideal for managing steel coils, ensuring careful and precise transportation.

- Charging Cranes: Essential for feeding raw materials into furnaces, these cranes are robust and highly durable.

Features and Specifications of Steel Mill Cranes

Steel mill cranes are engineered for exceptional performance under demanding conditions. Key features include:

- High Load Capacity: These cranes can lift loads ranging from 10 tons to over 500 tons, depending on the model.

- Durable Construction: Built with high-strength materials, they resist wear and deformation under heavy usage.

- Advanced Control Systems: Modern cranes are equipped with automated controls for precise operations.

- Heat Resistance: Components are designed to withstand the high temperatures typical in steel mills.

- Customizable Designs: Manufacturers can tailor cranes to meet specific operational requirements.

Applications in the Steel Industry

Steel mill cranes serve diverse roles in the steel industry, ensuring efficient material handling at every stage. Their applications include:

- Transporting molten steel from furnaces to casting stations.

- Handling raw materials like iron ore and scrap steel.

- Moving finished steel products such as coils, sheets, and bars to storage or shipping areas.

- Feeding rolling mills and other processing equipment with semi-finished products.

Safety and Maintenance Best Practices

Ensuring safety and regular maintenance is crucial for optimal crane performance. Best practices include:

- Conducting routine inspections to detect wear and potential failures.

- Training operators to follow safety protocols and use the equipment correctly.

- Implementing preventative maintenance schedules to reduce downtime.

- Equipping cranes with safety features like overload protection and emergency stop mechanisms.

Benefits of Steel Mill Cranes

Integrating steel mill cranes into operations offers significant advantages, such as:

- Increased Efficiency: Cranes streamline material handling, boosting productivity.

- Improved Safety: Automated systems minimize human exposure to hazardous conditions.

- Cost Savings: Reduced downtime and efficient operations lower operational expenses.

- Enhanced Precision: Advanced controls ensure accurate positioning of loads.

FAQ: Steel Mill Crane

What is the typical lifespan of a steel mill crane?

With proper maintenance, a steel mill crane can last 20-30 years, depending on usage and environmental conditions.

Can steel mill cranes be customized for specific tasks?

Yes, manufacturers offer customized solutions to meet unique operational needs, including load capacity, dimensions, and features.

What safety certifications are required for steel mill cranes?

Compliance with industry standards such as ISO, OSHA, and ASME is essential for ensuring crane safety and reliability.

How are steel mill cranes controlled?

Modern cranes use advanced control systems, including remote controls and automated programming, for precise operations.

What is the difference between ladle cranes and charging cranes?

Ladle cranes are designed for transporting molten steel, while charging cranes are used to feed raw materials into furnaces.

What does nybon crane group provide?

Free OEM/Free Design

Get A Quote Today

Welcome to send a free inquiry to —info@nybonmachinery.com

Your Trust-worthy Industrial Crane Supplier

Steel mill cranes are the backbone of efficient material handling in the steel industry. With their versatile applications, advanced features, and robust construction, these cranes significantly enhance productivity and safety.

By understanding their types, features, and benefits, steel producers can make informed decisions to optimize their operations and maintain a competitive edge in the market.