Understanding Crane Parts and Their Role in Industrial Lifting Equipment

Crane parts play a critical role in the safety, reliability, and efficiency of industrial lifting systems. Whether used in overhead cranes, gantry cranes, or jib cranes, each component contributes to stable lifting and long-term performance.

This article explains the main crane parts used in industrial applications and why proper component selection matters.

Why Crane Parts Matter in Industrial CranesWhy Crane Parts Matter in Industrial Cranes

High-quality crane parts ensure:

Safe lifting operations

Smooth crane movement

Reduced maintenance downtime

Longer service life of lifting equipment

Poor-quality or mismatched crane parts can lead to frequent failures and safety risks.

Main Types of Crane Parts

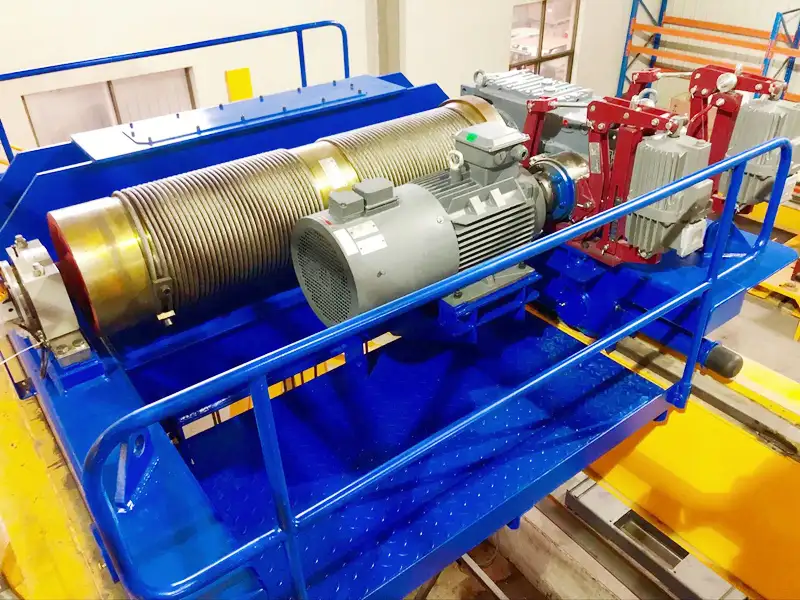

Hoisting Mechanism

The hoisting mechanism is responsible for lifting and lowering loads. It usually includes an electric hoist or winch assembly.

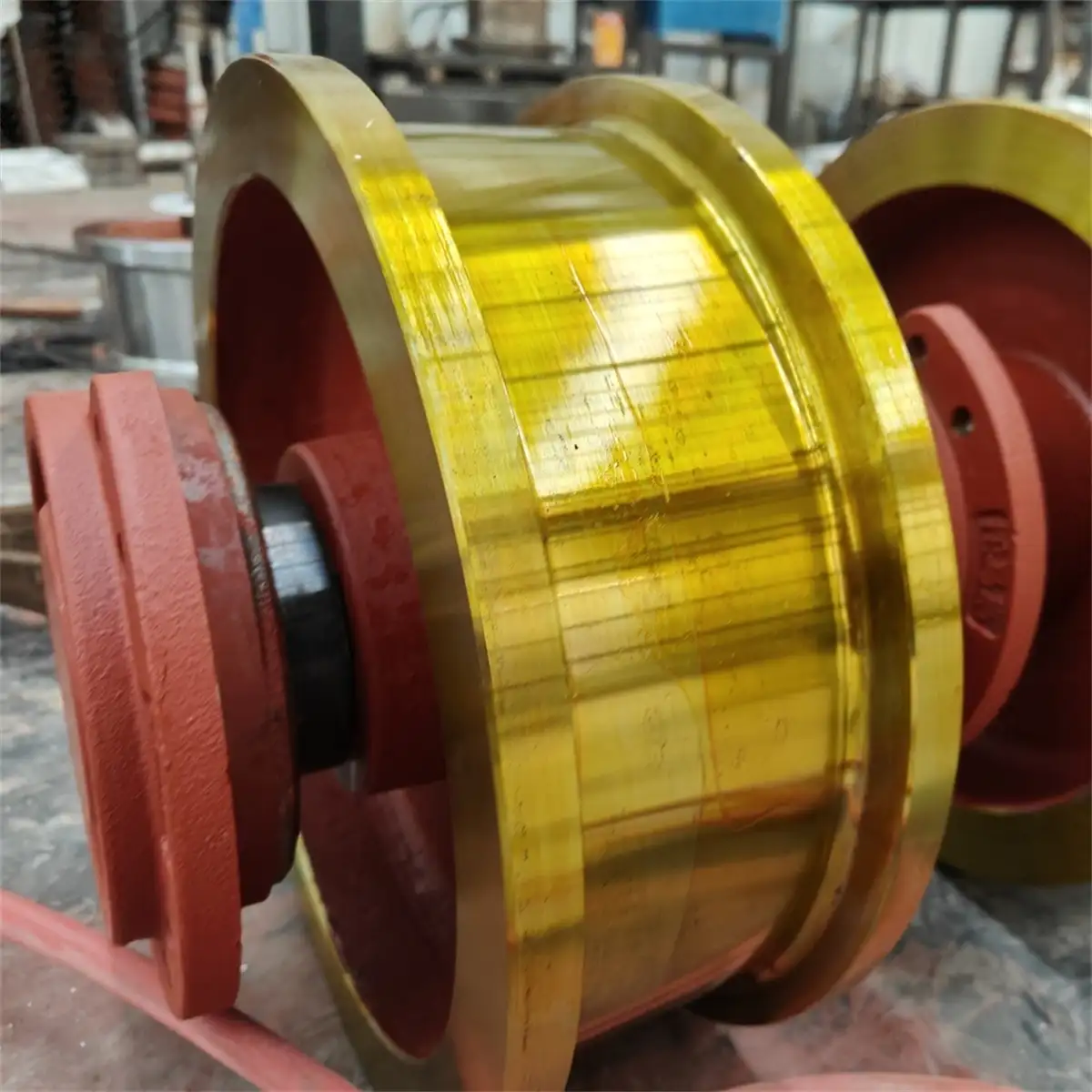

Crane Wheels and Wheel Assemblies

Crane wheels support the entire crane load and enable smooth travel along rails. They are essential crane parts for both overhead and gantry cranes.

Crane End Carriage

The end carriage connects the bridge girder to the traveling wheels, allowing the crane to move along the runway system.

Bridge Girder and Structural Parts

The bridge girder is the main load-bearing structure. Its design directly affects crane stability and lifting capacity.

Electrical and Control Components

Electrical crane parts include control panels, limit switches, cables, and remote control systems.

NYBON Crane

Customizable Solutions – Nybon Crane offers tailor-made cranes to meet specific requirements, including capacity, speed, and mounting options.

Standard Technical Parameters of Crane Parts (Reference)

| Item | Typical Range |

|---|---|

| Applicable Crane Type | Overhead / Gantry / Jib |

| Load Capacity Range | 0.5 – 200 tons |

| Material | Alloy Steel / Carbon Steel |

| Surface Treatment | Painted / Galvanized |

| Operating Environment | Indoor / Outdoor |

✅ All crane parts support customized manufacturing and matching.

Customization Options for Crane Parts

Different lifting systems require different component designs. Customized crane parts can include:

Non-standard dimensions

Heavy-duty materials

Special surface treatments

Customized electrical configurations

At Nybon Machinery, crane parts are designed to match specific crane systems and operating conditions.

Frequently Asked Questions (FAQ)

Q1: What are the most important crane parts?

Key crane parts include the hoisting mechanism, crane wheels, end carriage, bridge girder, and control system.

Q2: Are crane parts interchangeable between different crane types?

Some crane parts can be shared, but many components must be matched to specific crane designs.

Q3: Can crane parts be customized?

Yes. Dimensions, materials, and configurations can be customized based on application needs.

Q4: How often should crane parts be inspected?

Crane parts should be inspected regularly based on usage frequency and operating conditions.

Q5: Does Nybon Machinery supply crane parts separately?

Yes. Nybon Machinery supplies crane parts and customized components for industrial lifting systems.