Understanding Crane Safety: Best Practices for Safe and Efficient Lifting Operations

Crane safety is essential for ensuring that industrial lifting operations are conducted without incidents. Whether used in factories, construction sites, or warehouses, cranes are heavy-duty equipment that require specific safety measures to protect operators and other workers.

In this guide, we outline key crane safety guidelines that should be followed in every lifting operation.

Why Crane Safety Is Critical

Crane accidents can cause severe injuries and even fatalities. In addition to the human cost, accidents often lead to significant downtime, damaged equipment, and loss of productivity. By adhering to strict crane safety protocols, companies can reduce the risk of accidents and ensure smooth operations.

Key Crane Safety Guidelines

Conduct Regular Inspections

Regular inspections of crane components—such as the hoisting mechanism, control systems, and structural parts—are crucial for identifying wear or potential failures before they cause problems.

Operator Training and Certification

Proper crane operator training is essential. All crane operators should be certified and well-versed in both standard and emergency lifting procedures. Regular training helps minimize human error, which is a common cause of accidents.

Correct Load Handling and Weight Limits

Crane operators must understand the weight capacity of their equipment and avoid overloading. Overloading can lead to crane failure or dangerous accidents.

Safe Operation in Adverse Weather Conditions

Crane operations should be suspended during heavy winds, rain, or other extreme weather conditions. A safe operating environment ensures stable and secure lifting operations.

Use of Personal Protective Equipment (PPE)

Operators and workers should always wear appropriate PPE, such as hard hats, safety harnesses, and gloves, to protect against accidents during crane operations.

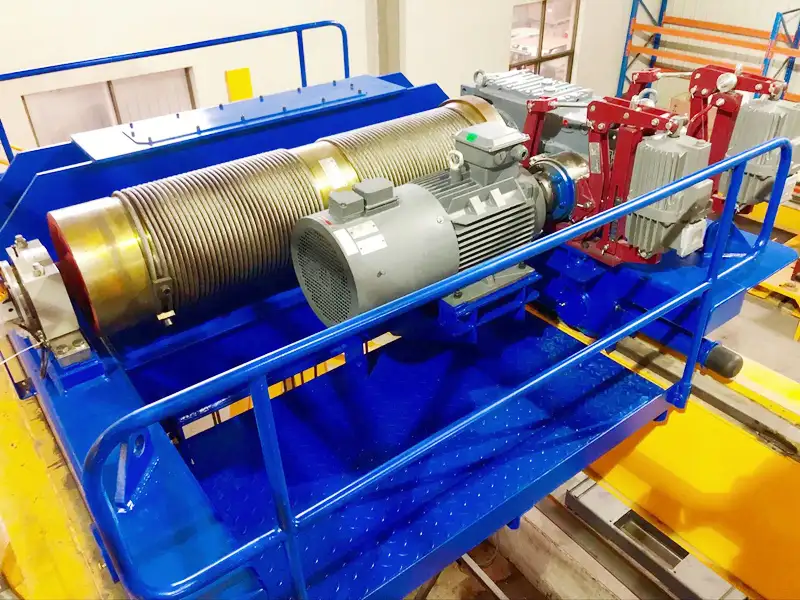

NYBON Crane

Customizable Solutions – Nybon Crane offers tailor-made cranes to meet specific requirements, including capacity, speed, and mounting options.

Crane Safety Maintenance Checklist

Daily Inspections

Check hoisting mechanisms, wire ropes, and chains for damage or wear.

Ensure brakes are functioning properly.

Verify that control systems are operating correctly.

Monthly Inspections

Inspect the crane’s structural components (e.g., girders, end carriages).

Test safety devices such as limit switches and emergency stop functions.

Annual Inspections

Conduct a thorough inspection of the entire crane system, including electrical systems, motors, and gearbox systems.

Replace any worn-out or faulty components.

Crane Safety Certification and Compliance

Crane operators and lifting equipment must comply with industry safety standards. This may include local regulations or international standards, such as those set by OSHA (Occupational Safety and Health Administration) or ISO (International Organization for Standardization).

Crane safety certification ensures that equipment and operators meet the required safety standards, reducing the likelihood of accidents.

Crane Safety Technology Innovations

Anti-Sway Systems

Modern cranes are equipped with anti-sway technology that helps prevent the load from swinging excessively during lifting.

Load Monitoring Systems

Crane systems with load monitoring can provide real-time data on lifting capacity and prevent overload.

Automated Crane Systems

Automated cranes reduce the likelihood of human error and enhance safety by utilizing advanced sensors and AI to monitor crane movements and loads.

Frequently Asked Questions (FAQ)

Q1: What are the most important crane safety protocols?

Key protocols include conducting regular inspections, providing operator training, and ensuring proper load handling.

Q2: How can overloading be prevented in crane operations?

Operators should be well-trained to understand the crane’s load capacity and use proper load assessment methods.

Q3: Is crane safety training mandatory?

Yes, crane operators should undergo regular training and certification to operate equipment safely.

Q4: Can crane safety technology help reduce accidents?

Yes, anti-sway systems, load monitoring, and automated crane systems can significantly improve safety.

Q5: Does Nybon Machinery provide crane safety solutions?

Yes. Nybon Machinery offers comprehensive crane safety systems, including load monitoring and anti-sway technology.